There are many advantages of using a punch press. In this article, we will cover some of them, from Turret punches to hydraulic cylinder, and quick-change tooling. In addition, you’ll learn how CNC programming can make your punch press more efficient and effective. Hopefully, you’ll be able to decide whether or not a punch press is right for your production line.

Hydraulic cylinder

A hydraulic cylinder is a device that is used to press a metal piece using high pressure. Its power is measured in psi, which is equivalent to 88 tons. This tool makes use of liquids to transmit pressure, which makes it highly efficient. The pressure applied to the hydraulic cylinder causes it to move upward or downward. The hydraulic cylinder uses an integrated cartridge valve block and one-way valves to control the flow of the hydraulic oil.

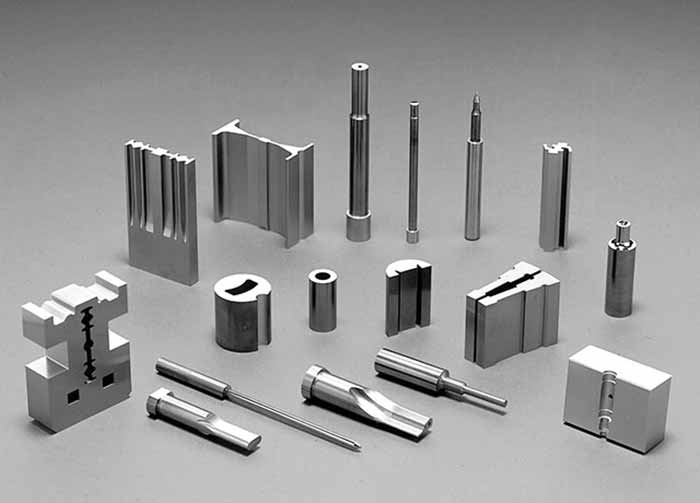

A hydraulic cylinder for punch press is an effective tool for manufacturing precision parts and components. Its simple structure, high efficiency and fast production speed make it a good choice for large and small batch production. The hydraulic cylinder helps achieve accurate depth, changeable shape, and precise slider velocity and pressure. In addition, it allows the user to fabricate components to specific orders.

Quick-change tooling

Quick-change tooling allows you to change the tooling without resetting the press. This feature is especially useful when using different punch hole sizes. You can change the tooling by simply changing the punch holder. The quick-change tooling allows you to change punches quickly and save time.

A punch press is a machine that cuts and shapes flat sheets of material with a punch. They can be large CNC-operated or small manually operated. Both types of punch presses are large machines with a C-type frame. It is centered so that the frame does not deflect when the punch is made.

CNC programming

CNC programming of punch press is a process that helps automate the process of punching sheet metal and forming complex shapes. CNC programming helps create components with consistent dimensions and shapes, while reducing time and cost by eliminating rework. This process utilizes computer-aided design (CAD) information. The information may be presented in 2D or 3D formats. CNC punching programs use this information to set up flat sheet metal pressing, assign proper tooling, and determine the most effective layout of components from a sheet of metal. This layout is known as the CNC nest. The more CNC punched components are produced from a given sheet of metal, the cheaper they are to produce, Browse around this website.

Using CNC punch press programming can significantly cut waste and improve overall productivity. CAD-based solutions are an essential part of CNC punching. These sophisticated CAD/CAM systems help manufacturers optimize material use and maximize functionality.

High yield of components

CNC punching can be used to automate the process of punching sheet metal panels. The benefits of CNC punching are that the designer does not need to be an expert in punching. He just needs to keep a few design considerations in mind when creating CNC punched components. Listed below are some of the most important design considerations that are relevant to CNC punching.

Summary:

High press force – The high press force allows the machine to produce more workpieces in a single cycle. It also allows for high production efficiency. Long press stroke – A punching press with a long press stroke is essential for some parts of the machining process. For example, a can needs a press stroke of 10-20 mm, whereas a silicon sheet requires a shorter stroke.